R & S offers fast, professional installation of industry standard hollow metal doors and frames, and all related hardware, to insure that your doors meet all applicable building codes. We also supply contractor packages for installation by others. Email us today for a free estimate or for more detailed information on our Hollow Metal Doors.

Hollow Metal Doors and Door Frames are an industry standard in commercial, industrial and institutional construction projects. In sum, they combine durability with economy.

Benefits

- Factory prepped to receive hardware and vision panels.

- Available in 16 GA or 18 GA.

- Welded or knock down door frames

- Gray primer coat paint.

- You install or use our experienced installers.

- Quick Delivery for Most Common Flush Door Sizes.

- Constructed with honeycomb core, urethane foam core, vertical steel stiffened core; flush or stile and rail.

Mesker Door

Mesker Door offers a complete line of hollow metal doors in face sheet gauges ranging from 20 to 14. Doors are typically made of cold rolled steel or galvanized steel. Moreover, all are insulated as standard with fully bonded, durable polystyrene cores (urethane, honeycomb and fiberboard are also available).

The door line consists of the standard N Series (non handed door), Six-Panel, Steel Stiffened, Wood grain, 14 Gauge and Bullet Resistant. Undoubtedly, the combined durability and economy of these doors make them an outstanding choice for all of your hollow metal needs.

N Series

- CLOSER REINFORCEMENT: Every N Series door is furnished with a closer reinforcement box.

- EXTRA LONG LIFE: The key to the N-Series sag resistance is the extra long 3/16 hinge reinforcement.

- YOUR CHOICE OF FOUR CORES: Polystyrene, Honeycomb, Urethane, and Fiberboard.

- LOCK REINFORCEMENT: Thye N Series Door can be prepared for Govt. 161 cylindrical locks with a 2 3/4 backset (ANSI A115.2 lock front), or a Govt. 86 mortise lock with a 2 3/4 backset (ANSI A115.1 lock front.) N Series Doors are also available prepped for sectional trim, panic and electric devices.

- HEMMED EDGE: The hemmed edge of the N Series door offers an extra smooth transition between faces.

- UNIVERSAL HANDING: N Series Doors fit both right and left hand openings, due to the double hole pattern and reversible filler plate

Republic Doors and Frames

Republic also offers a complete line of standard and specialty hollow metal doors to fit your architectural needs.

- All Republic doors are available in 20, 18, 16, & 14 gauge cold rolled and galvanized steel.

- All doors come with a 3/4″ cell honeycomb core as standard, providing every door with a smoother, flatter, and stronger door.

- Republic honeycomb doors are available in a complete range of fire ratings (20 minute up to 3 hours) and are certified under both Underwriters Laboratories and Warnock Hersey/ITS.

- Manufactured from stretcher level quality steel and are thoroughly cleaned and phosphatized inside and out, offering excellent corrosion resistance and paint adhesion.

Optional Door Cores

- Polystyrene (Solid Core) – 1 lb density expanded polystyrene per ASTM 578 U-Factor of .13

- Polyurethane (Solid Core) – 2 lf density polyurethane per ASTM C591 U-Factor of .10

- Steel Stiffened – Vertical hat shaped stiffeners of 20, 18, and 16 gauge with mineral wool or fiberglass batting between stiffeners. Welded a maximum of 6″ apart and on 5″ centers.

- Temperature Rise/Mineral Fiberboard – Mineral fiberboard capable of withstanding a maximum of 250° temperature rise in 30 minutes. U-Factor of .26

DM Series Full Flush Doors

Republic´s DM series doors are available in 18 or 20-gauge cold rolled steel or galvanized (A60) steel. Republic´s “McKenzie Edge” lock edge is continuously lap seam welded and planished, providing a near seamless appearance – SDI levels 1 and 2 – Physical performance level A.

Features

- 1 3/4″ (44.4) full flush design, rated for light to extra heavy-duty use

- 3/4″ (19) cell honeycomb core 100% bonded to skins to provide exceptional strength and flatness

- Hinge edge is non-beveled and reinforced with a full height 16 gauge steel channel projection welded at a maximum of 5″ on center with an additional 9 gauge reinforcement plate at each hinge location, providing more than 3/16″ (5) of total reinforcement

- 16 gauge flush top and inverted bottom channels projection welded to both skins every 2 1/2″ on center

- Moreover, doors are prepared for 4 1/2″ standard or heavy weight, full mortise template hinges

- Non-handed design (square lock edge)

- They also come standard with 1 1/2 hour mylar Underwriters Laboratories fire label

- Doors are then thoroughly cleaned, phosphatized, and primed with a coat of force cured rust inhibiting primer that meets and/or exceeds the requirements of ANSI A250.10 (120 hour continuous salt spray test per ASTM B117 and 240 hour continuous humidity test per ASTM D4585)

- Finally, doors are individually packaged and fully plastic wrapped to prevent damage

Available Options

- 14 gauge closer reinforcement (standard option)

- 12 gauge closer reinforcement

- A60 galvanized steel

- Finish paint (Republic standard and custom colors)

- Standard cylindrical or mortised lock hardware

DL Series Full Flush Doors

Republic´s DM series doors are available in 18 or 20 gauge cold rolled steel or galvanized (A60) steel. Republic´s “McKenzie Edge” lock edge is continuously lap seam welded and planished, providing a near seamless appearance – SDI levels 1 and 2 – Physical performance level A.

Features

- 1 3/4″ (44.4) full flush design, rated for light to extra heavy-duty use

- 3/4″ (19) cell honeycomb core 100% bonded to skins to provide exceptional strength and flatness

- Hinge edge is non-beveled and reinforced with a full height 16 gauge steel channel projection welded at a maximum of 5″ on center with an additional 9 gauge reinforcement plate at each hinge location, providing more than 3/16″ (5) of total reinforcement

- 16 gauge flush top and inverted bottom channels projection welded to both skins every 2 1/2″ on center

- In addition, doors are prepared for 4 1/2″ standard or heavy weight, full mortise template hinges

- Non-handed design (square lock edge)

- They also come standard with 1 ½ hour mylar Underwriters Laboratories fire label

- Doors are then thoroughly cleaned, phosphatized, and primed with a coat of force cured rust inhibiting primer that meets and/or exceeds the requirements of ANSI A250.10 (120 hour continuous salt spray test per ASTM B117 and 240 hour continuous humidity test per ASTM D4585)

- Finally, doors are individually packaged and fully plastic wrapped to prevent damage

Available Options

- 14 gauge closer reinforcement (standard option)

- 12 gauge closer reinforcement

- A60 galvanized steel

- Finish paint (Republic standard and custom colors)

- Standard cylindrical or mortised lock hardware

DE Series Full Flush Doors

Republic’s DE series doors are available in 14, 16, 18, and 20 gauge cold rolled steel or galvanized (A60) steel. Face sheets are subsequently continuously projection welded to hinge and lock channels on 5″ centers. SDI Levels 1, 2, 3 and 4 – Physical performance level A, B, C, D.

Features

- 1 3/4″ (44.4) full flush design, rated for light to extra heavy-duty use

¾” (19) cell honeycomb core 100% bonded to skins to provide exceptional strength and flatness

- Hinge edge is non-beveled and reinforced with a full height 10 gauge steel channel projection welded at a maximum of 5″ on center

16 gauge flush top and inverted bottom channels projection welded to both skins every 2½” on center

- Lock edge is non-beveled and reinforced with a continuous 14 gauge channel, mortised and cylindrical lock reinforcements are integral 14 gauge reinforcements

- In addition, doors are prepared for 4½” standard or heavy weight, full mortise template hinges

- Non-handed design (square lock edge)

- Doors are then thoroughly cleaned, phosphatized, and primed with a coat of force cured rust inhibiting primer that meets and/or exceeds the requirements of ANSI A250.10 (120 hour continuous salt spray test per ASTM B117 and 240 hour continuous humidity test per ASTM D4585)

- Finally, doors are individually packaged and fully plastic wrapped to prevent damage

Available Options

- 14 gauge closer reinforcement (standard option)

- 12 gauge closer reinforcement

- A60 galvanized, G90 galvanized, or textured wood-grain or leather-grain steel

- Continuously welded seamless design or filled seamless design

- Lock edge beveled 1/8″ in 2″

- Polystyrene, mineral fiberboard, and polyurethane solid cores

- 20, 18, or 16 gauge vertical steel stiffeners (20 gauge standard)

- Sizes available: Minimum 1″0″ (305) x 1″0″ (305), Maximum 5″0″ (1524) x 10″0″ (3048)

- Also available, finish paint (Republic standard and custom colors)

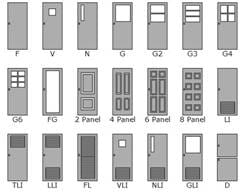

DL Series Embossed Panel Doors

Commercial Steel Door Performance with Decorative Panel Designs. Republic offers a wide variety of embossed panel insulated doors such as our traditional 6-panel design, 8′ 6-panel design with elongated panels, 2-panel colonial design, 4 panel, and 8 panel designs. Doors are available in 18, and 20 gauge cold rolled steel or galvanized (A60) steel. Face sheets are subsequently continuously projection welded to hinge and lock channels on 5″ centers. SDI Levels 2 and 3 – Physical performance level A.

Features

- 1 3/4″ (44.4) design, rated for light to extra heavy-duty use

- Polystyrene core (1 pound density) 100% bonded to skins to provide exceptional insulation, strength, and flatness

- Hinge edge is non-beveled and reinforced with a full height 16 gauge steel channel projection welded at a maximum of 5″ on center with an additional 9 gauge reinforcement plate at each hinge location, providing more than 3/16″ (5) of total reinforcement

16 gauge flush top and inverted bottom channels projection welded to both skins every 2 1/2″ on center

- Lock edge is non-beveled and reinforced with a continuous 16 gauge channel, mortised and cylindrical lock reinforcements are integral 16 gauge reinforcements

- Also, doors are prepared for 4 1/2″ standard or heavy weight, full mortise template hinges

- Non-handed design (square lock edge)

- They also come standard with 1 1/2 hour Mylar Underwriters Laboratories fire label

- Doors are then thoroughly cleaned, phosphatized, and primed with a coat of force cured rust inhibiting primer that meets and/or exceeds the requirements of ANSI A250.10 (120 hour continuous salt spray test per ASTM B117 and 240 hour continuous humidity test per ASTM D4585)

- Additionally, doors are individually packaged and fully plastic wrapped to prevent damage

Available Options

- 14 gauge closer reinforcement (standard option)

- 12 gauge closer reinforcement

- A60 galvanized, or textured wood-grain (wood grain embossed are available as prime painted only – factory stain not available)

- Continuously welded seamless design or filled seamless design

- Lock edge beveled 1/8″ in 2″

- Sizes available: Minimum 2′6″ x 6′8″, Maximum 3′8″ x 7′2″ (20 gauge available in 3070 or smaller only)

4″ hinges (square edge only)

- Half glass light kits (limited sizes available)

- Finish paint (Republic standard and custom colors)

DM and DL Series UNIFIT™ Replacement Doors

Republic′s Unifit™ series doors are available in 16, 18, and 20-gauge cold rolled steel or galvanized (A60) steel. Republic face sheets are subsequently continuously projection welded to hinge channels on 5″ centers. SDI Levels 2 and 3 – Physical performance level A.

Features

- 1 3/4″ (44.4) full flush design, rated for light to extra heavy-duty use

- 3/4″ (19) cell honeycomb core 100% bonded to skins to provide exceptional strength and flatness

- Hinge edge is non-beveled and reinforced with a full height 10 gauge steel channel projection welded at a maximum of 5″ on center. Hinge channel depth is set at .190 and can be used for heavy or standard weight hinges

16 gauge flush top and inverted bottom channels projection welded to both skins every 2 1/2″ on center

- Furthermore, lock edge is non-beveled and reinforced with a continuous 16 gauge channel (DL series), mortised and cylindrical lock reinforcements are integral 16 gauge reinforcements

- Non-handed design (square lock edge)

- Doors are then thoroughly cleaned, phosphatized, and primed with a coat of force cured rust inhibiting primer that meets and/or exceeds the requirements of ANSI A250.10 (120 hour

- Additionally, continuous salt spray test per ASTM B117 and 240 hour continuous humidity test per ASTM D4585)

- In order to prevent damage, doors are individually packaged and fully plastic wrapped

Available Options

- 14 gauge closer reinforcement (standard option)

- 12 gauge closer reinforcement

- A60 galvanized, G90 galvanized, or textured wood-grain

- Polystyrene, mineral fiberboard, and polyurethane core

- 20, 18, or 16 gauge vertical steel stiffeners (20 gauge standard)

- Sizes available: Minimum 1′0″ (305) x 1′0″ (305), Maximum 5′0″ (1524) x 10′0″ (3048)